Concrete grinders are crucial instruments for smoothing and polishing concrete surfaces. These machines have various sizes and types, ranging from handhelds to bigger industrial units. Concrete grinders are essential in the construction and industrial sectors for preparing concrete surfaces for finishing touches such as polishing or coating applications.

Epoxy Moncton has done some search and wanted to share how they help to improve the safety and attractiveness of buildings and infrastructure projects by producing smooth and level surfaces. Their value stems from their capacity to improve the functionality and look of concrete structures.

Early Developments (Late 19th and Early 20th Century)

In the late nineteenth and early twentieth centuries, the building sector saw the advent of crude technologies for grinding concrete surfaces. These approaches sought to smooth and level concrete, which was gaining popularity as a building material.

Manual grinding techniques were popular during this period, with construction workers using handheld instruments such as chisels and abrasives to grind concrete surfaces manually. This labor-intensive technique necessitated skilled artistry and a significant amount of physical exertion.

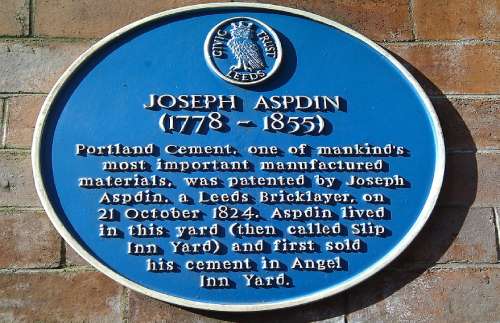

Several prominent persons contributed significantly to the early development of concrete grinding technology. Among them, John Smeaton, known as the “Father of Civil Engineering,” experimented with numerous grinding procedures to improve the strength and longevity of concrete structures. Joseph Aspdin, well-known for creating Portland Cement, also enhanced concrete grinding procedures to provide smoother and more consistent results. These pioneers paved the way for the advancement of concrete grinding technology over the next several centuries.

| Period | Development |

|---|---|

| Late 19th Century | Introduction of early concrete grinding methods |

| Early 20th Century | Exploration of manual grinding techniques in construction |

| Mid-20th Century | Introduction of powered concrete grinders |

| Late 20th Century | Adoption of diamond grinding tools and techniques |

| Present | Technological advancements in concrete grinding |

Industrial Revolution and Innovation (Mid to Late Twentieth Century)

The Industrial Revolution constituted a watershed moment in concrete grinding technology, ushering in an era of fast innovation and mechanization. With the onset of industrialization, there was an increased demand for quicker and more efficient construction methods, which led to advancements in concrete grinding technology.

One of the most significant innovations during this period was the advent of powered concrete grinders. These machines transformed the grinding process by substituting manual labor with motorized tools, resulting in much higher productivity and precision in concrete surface preparation.

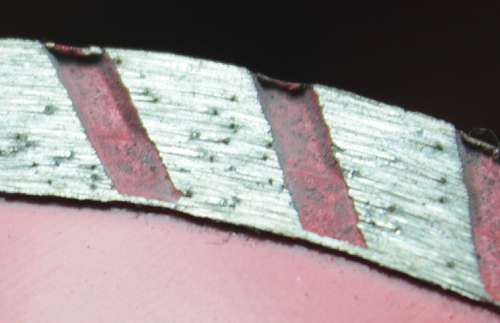

Grinding processes and machinery continued to improve during the mid to late twentieth century. Diamond-tipped grinding tools and more powerful grinding equipment allowed contractors to achieve better finishes and more accuracy in concrete grinding applications.

Several businesses, including Husqvarna, HTC, and Lavina, rose to prominence in the development of modern concrete grinders. These firms pioneered cutting-edge technology and equipment that have since become industry standards for concrete surface preparation and polishing. Their contributions have helped form the present landscape of concrete grinding, which is now a key component of construction and rehabilitation projects worldwide.

The Rise of Modern Concrete Grinding (Late Twentieth Century to Present)

With the widespread use of diamond grinding equipment and procedures in the late twentieth century, concrete grinding underwent a considerable change. Diamonds are highly effective abrasives for grinding concrete surfaces, providing greater durability and precision than typical grinding materials.

During this time, the concrete grinding industry grew into new markets beyond construction. Concrete grinding has become indispensable for generating smooth and polished concrete surfaces in various scenarios, including residential restorations, commercial structures, and industrial uses.

Technological improvements influenced the growth of concrete grinders, resulting in more efficient and adaptable devices. Planetary grinders and remote-controlled devices allowed contractors to complete larger jobs more quickly and precisely while improving dust control and environmental sustainability.

The impact of concrete grinding on construction techniques and architectural design has been significant. Concrete grinding, which can transform drab and uneven concrete surfaces into sleek and polished finishes, has become an essential component of modern construction projects. Architects and designers today have more options for combining polished concrete floors and surfaces into their projects, resulting in unique and visually appealing architectural spaces.

Future Trends & Innovations

Emerging technologies are constantly transforming the landscape of concrete grinding, with advances aimed at increasing efficiency, sustainability, and precision. Robotic grinding systems and artificial intelligence-driven machines are transforming concrete surface preparation and finishing, promising faster, more accurate, and cost-effective results.

| Company | Contribution |

|---|---|

| Bosch | Leading manufacturer of concrete grinders |

| Husqvarna | Innovator in diamond tooling technology |

| Diamatic | Provider of high-quality grinding equipment |

| HTC | Pioneer in remote-controlled grinding |

| Lavina | Known for innovative grinding solutions |

Concrete grinders are prepared to play an essential part in sustainable construction practices, with applications ranging from recycling and repurposing concrete waste to lowering carbon emissions connected with traditional construction methods. As sustainability becomes more important in the construction industry, concrete grinders are expected to improve to satisfy the demand for eco-friendly solutions, thereby contributing to a more environmentally responsible approach to building development.

Forecasts for the future of concrete grinding technology are optimistic, with continued expansion and innovation expected in the following years. As the construction industry embraces digitization and automation, concrete grinders are anticipated to become more advanced and affordable, providing contractors and designers with hitherto unattainable surface preparation and finishing capabilities. With continued R&D efforts, the future promises promising prospects to improve concrete grinding technology’s efficiency, sustainability, and versatility.

Get Connected To Us!

Concrete grinders have progressed dramatically since their introduction, owing to the demand for more efficient and precise surface preparation techniques. Concrete grinding has evolved from manual procedures to sophisticated, powered gear, demonstrating constant innovation and development. Concrete grinders have become indispensable in various industries because of the introduction of diamond grinding equipment and technological improvements.

As we move to the future, emerging technologies have the potential to revolutionize concrete and further grinding by improving capacities and sustainability in construction. Contact Epoxy Moncton today to see how our experience can help you take your concrete grinding projects to the next level.